Global Superabsorbent Fiber Yarns Market: Engineering Advanced Fluid Management

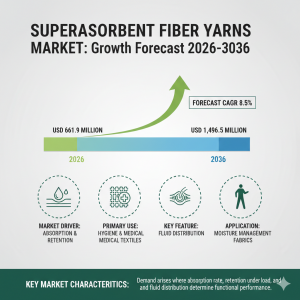

The superabsorbent fiber yarns market is projected to grow from USD 661.9 million in 2026 to USD 1,496.5 million by 2036, at a CAGR of 8.5%.

NEWARK, DE, UNITED STATES, January 22, 2026 /EINPresswire.com/ -- The global Superabsorbent Fiber (SAF) Yarns Market is entering a phase of high-velocity growth, opening 2026 with a valuation of USD 661.9 million and projected to reach USD 1,496.5 million by 2036. This trajectory represents a robust 8.5% CAGR, fueled by the rising demand for high-performance moisture management in hygiene, medical, and technical textiles.

Unlike traditional absorbent materials, SAF yarns are engineered to lock away liquids under significant pressure, making them indispensable for applications where dimensional stability and leakage prevention are critical.

Market Dynamics: Absorption Kinetics and Structural Integrity

The demand for SAF yarns is driven by the need for precise fluid handling. These materials must maintain their physical integrity while absorbing several hundred times their own weight in liquid.

Key Performance Drivers:

• Retention Under Load (RUL): Crucial for adult incontinence and infant care, where body weight can "squeeze out" fluids from standard fibers.

• Uptake Speed: Fast absorption kinetics are required to prevent surface runoff and ensure skin dryness.

• Gel Stability: After swelling, the fiber must remain stable to prevent "gel blocking," which can impede further fluid distribution.

• Process Reliability: Manufacturers prioritize yarns that run cleanly on high-speed knitting and weaving equipment with minimal dust generation or static issues.

Request For Sample Report | Customize Report | Purchase Full Report

https://www.futuremarketinsights.com/reports/sample/rep-gb-31615

Segmentation Analysis: Polymers and Applications

Polymer Type: The Role of SAP-Loaded Cellulosics

• SAP-Loaded Cellulosic Fibers (34% Share): The leading segment. These fibers combine the natural wicking ability of cellulose with the extreme capacity of Superabsorbent Polymers (SAP). They are favored for hygiene products due to their familiar converting behavior.

• SAP-Loaded Synthetic Fibers: Used in applications requiring higher wet strength and abrasion resistance, such as industrial wipes or cable protection.

• Pure Superabsorbent Fibers: Target specialized roles where maximum uptake capacity is the only priority, often used in ultra-thin absorbent cores.

Application: Beyond Basic Hygiene

• Hygiene & Incontinence (42% Share): The dominant application. Growth is driven by the aging global population and the resulting demand for high-performance adult care products.

• Medical & Wound Care: SAF yarns are integrated into advanced dressings to manage exudate while keeping the wound bed moist but not macerated.

• Cables & Industrial Uses: Used as "water-blocking" yarns in fiber optic and power cables. If the cable jacket is breached, the yarns swell to create a waterproof seal, preventing internal corrosion.

Regional Growth Patterns

Regional demand for superabsorbent fiber yarns is largely dictated by local manufacturing density and the maturity of regional healthcare systems. China leads global growth with a 9.7% CAGR, functioning as a massive production hub for both domestic medical disposables and international hygiene exports. In the United States, an 8.2% CAGR is propelled by high clinical standards for advanced wound care and the steady expansion of the adult incontinence segment. Similarly, Germany maintains a strong 8.1% CAGR, supported by centralized technical governance and a reputation for high-quality medical textile engineering. In South Korea, a 7.7% CAGR reflects the widespread adoption of standardized product platforms across multiple hygiene lines, while Japan follows with a 7.0% CAGR in a mature, specification-driven market where the primary focus remains on achieving ultra-consistent fiber quality.

Competitive Landscape: The Power of Inclusion

Success in the SAF yarns market depends on specification ownership. Because these yarns are used in regulated medical and hygiene products, once a yarn is qualified, it is rarely substituted.

Leading Industry Participants:

• BASF & Evonik: Dominant in SAP chemistry and high-capacity polymer systems.

• Nippon Shokubai: Specializes in polyacrylate fibers for ultra-thin core designs.

• Kelheim Fibres: A key innovator in cellulosic-based superabsorbent fibers.

• Fitesa & Fibertex Personal Care: Major converters that integrate SAF technology directly into nonwoven structures.

Strategic Outlook: 2026–2036

The rise to USD 1.49 billion by 2036 will be defined by the transition from simple absorbent "pads" to engineered, multi-layer textile structures. Future innovation is expected to focus on sustainable and bio-based superabsorbents to meet tightening environmental regulations regarding disposable hygiene waste.

Similar Industry Reports

Carbon-Neutral Fiber Yarns Market

https://www.futuremarketinsights.com/reports/carbon-neutral-fiber-yarns-market

Traceable Blockchain-Tagged Fiber Yarns Market

https://www.futuremarketinsights.com/reports/traceable-blockchain-tagged-fiber-yarns-market

Superabsorbent Polymer Market

https://www.futuremarketinsights.com/reports/superabsorbent-polymer-market

Sudip Saha

Future Market Insights Inc.

+ +1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.